Long Delivery Times Make Remanufacturing The Attractive Alternative

First the corona pandemic, then a shortage of raw materials and staff (because the economy picked up again) and now the war between Russia and Ukraine: these are all causes of long delivery times and ever-increasing production costs across all industries. Electronic car parts contain many components that are currently very scarce and this does not look like it will change in the short term. Alternatives are therefore increasingly being looked at to become less dependent on suppliers, such as used and remanufactured parts. The second option is especially in many ways a very interesting alternative.

More Than 90% is Reused

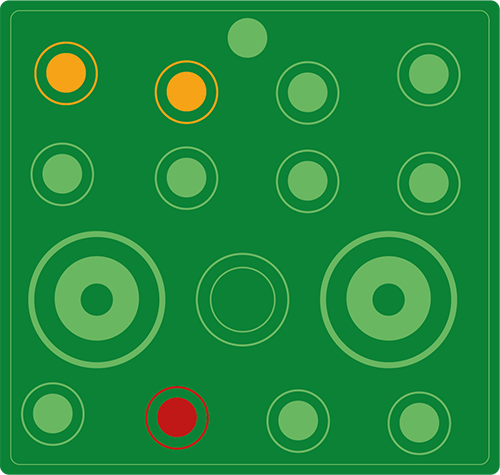

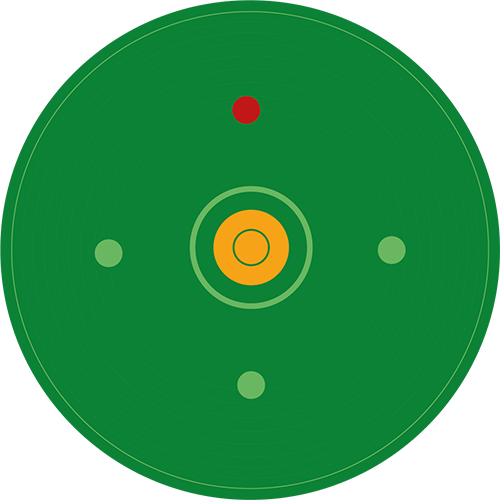

The major advantage of remanufacturing over a new part is the reuse of components, which saves both labor costs and raw materials. More than 90% of the parts can be reused. We can clarify this best with a schematic drawing of the three main components of an ABS system that makes this clearer.

PCB |

HCU |

Pump motor |

|

|

|

- Green = reused after checking and extensive testing

- Yellow = preventive replacement

- Red = Replace faulty component

The fact that we reuse so much at ACTRONICS does not mean that we leave all these parts unprocessed. Each part first undergoes an inspection and is then cleaned and/or remanufactured. Consider, for example, additional actions such as blasting and coating. A remanufactured product thus obtains the desired level of quality. Despite these actions, huge savings are made on raw materials.

Short Delivery Times

At the moment, perhaps the best argument for opting for a remanufactured product is the short delivery time. Remanufactured parts are much less dependent on new components and raw materials, so it is possible to turn parts around quickly. Of course second-hand/demolition parts have the same advantage, but frankly you cannot compare these parts with a new or remanufactured part. After all, there is a huge difference in quality.

Good for the Environment and Cost Price

Anyone who opts for remanufacturing therefore indirectly chooses to protect the environment as much as possible. This good gesture is also rewarded with a low cost price. A remanufactured part is no less than 60% to 80% cheaper than new. Also, you have nothing to worry about in terms of quality, because all defective and all known weak components are replaced, so that a remanufactured part reaches the same level of quality as a new part.

So if you are looking for a quality product with a short delivery time, remanufacturing is the alternative to get the car back on the road for an affordable price. Our product specialists are happy to assist you!

da

da de

de es

es fr

fr it

it nb

nb nl

nl pt

pt sv

sv fi

fi