The brake booster and electric cars: what is it and how does it work?

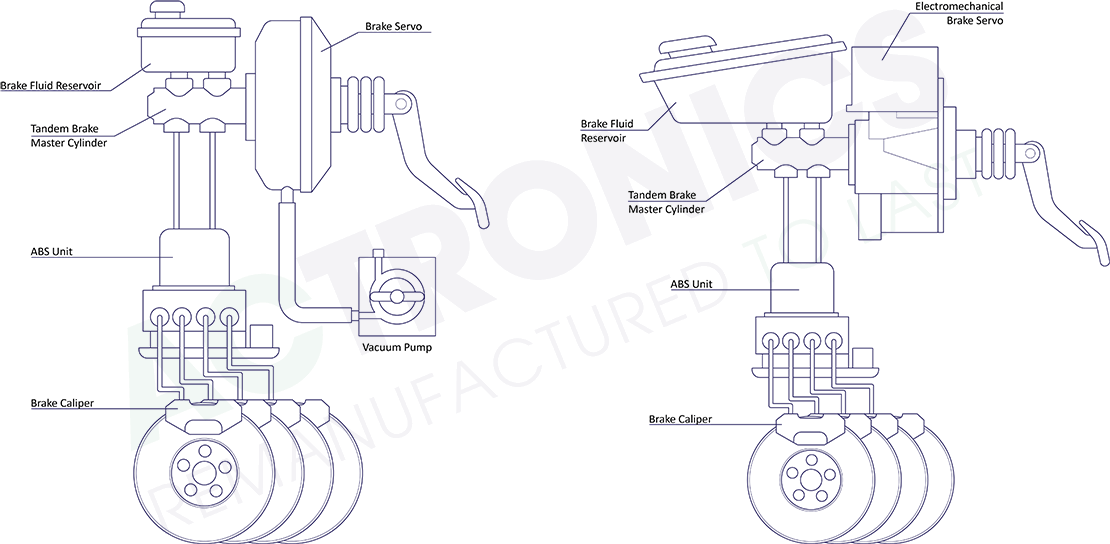

A conventional brake booster is designed to increase pedal pressure by a factor of 3 to 4. To achieve this, clever use is made of the vacuum that is created when the engine is running. A diaphragm divides the brake booster into two chambers: the pedal side and cylinder side. Both rooms have the same negative pressure at rest. When the brake pedal is pressed, the space on the pedal side will open, allowing outside air to flow in: overpressure is created. This overpressure supports the pedal force so well that the final brake pressure is 3 to 4 times higher than with a system without a brake booster. Unfortunately, this type of brake booster has one major drawback: the principle is completely based on the vacuum of a running combustion engine. An electric motor does not create a vacuum.

Photo: Conventional, vacuum-based brake booster vs Modern, Electromechanical brake booster

Electromechanics offers the solution

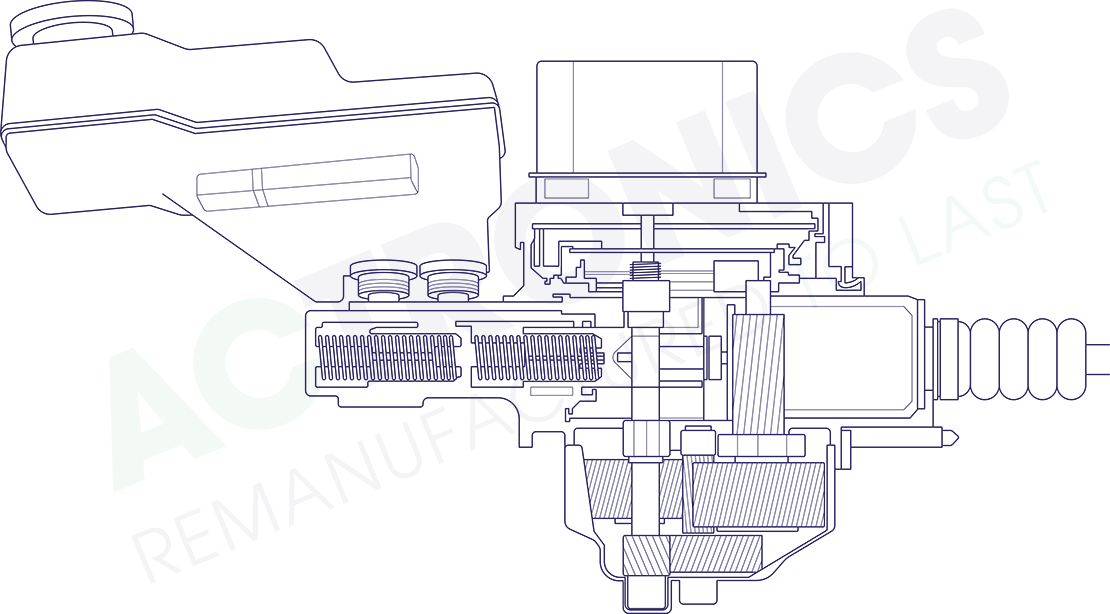

To solve this problem, a new generation of brake booster has been developed. Bosch calls it iBooster, but the official term is 'electromechanical brake booster'. With this system, the pin of the master brake cylinder still has a direct connection to the brake pedal, but in this case the pedal force is amplified by an electric motor with an ingenious free-running gear system. As a result, the brake booster has no longer become a static, but a dynamic system: the degree of assistance can in theory be adjusted per situation, up to a support of no less than 8 kN (more than 10x pedal pressure!). Autonomous braking is also possible. This system can now be found in several Tesla models.

Different variations on the concept

However, Bosch is not the only manufacturer with new ideas. Continental has also found an effective solution. The new ABS system is called MK C1. Simply explained, this is a conventional Continental MK 100 that uses the hydraulic pump to actuate the brake pedal. Unlike the Bosch system, the master cylinder pin no longer has a direct connection to the brake pedal. In this case, the master brake cylinder is integrated into the existing design and divided into two parts: the part that provides the characteristic hydraulic feeling in the pedal and the part that actually provides the braking function. The ECU receives input from the pedal travel sensor and then determines whether and how much brake pressure should be built up. A brake booster has therefore become completely unnecessary. The MK C1 is not cheap and many people have to get used to the 'brake by wire' idea, but the end product is light, small and has few moving parts. In addition, the brake pressure build-up can be controlled very quickly and very precisely. Both Audi (E-tron) and Alfa Romeo (Giulia) have already opted for this system.

Photo: Example of an electromechanical brake servo from the Volkswagen ID.4

da

da de

de es

es fr

fr it

it nb

nb nl

nl pt

pt sv

sv fi

fi