Easytronic and Selector Motors – Scots Auto Scene

On the outside there’s not much difference between the Durashift and Easytronic clutch actuators, however the ECU on the inside is where the difference lays. Because the ECU and the software cannot be seen very easily, another way of differentiating between the two is that the Easytronic system is on Vauxhall vehicles and the Durashift system is found on Ford’s & Mazda’s.

Rather than putting big, bulky and heavy automatic transmissions into a vehicle, manufacturers are able to construct every vehicle (manual and automatic transmission) with the same manual gearbox. The only thing needed to go from manual to an automatic transmission is a mechatronics unit that controls the clutch and the gears.

Rather than putting big, bulky and heavy automatic transmissions into a vehicle, manufacturers are able to construct every vehicle (manual and automatic transmission) with the same manual gearbox. The only thing needed to go from manual to an automatic transmission is a mechatronics unit that controls the clutch and the gears.

Alongside the clutch actuator, there will be a pair of selector motors. These are controlled by the mechatronics and will select the required gear when told too by the clutch actuator. Our testing and remanufacturing methods for these units have changed. We now require the need to send both the actuator and the selector motors.

We believe having both units and testing them together as they would be on the vehicle not only provides better test results but means we are able to offer an improved, more reliable remanufacture.

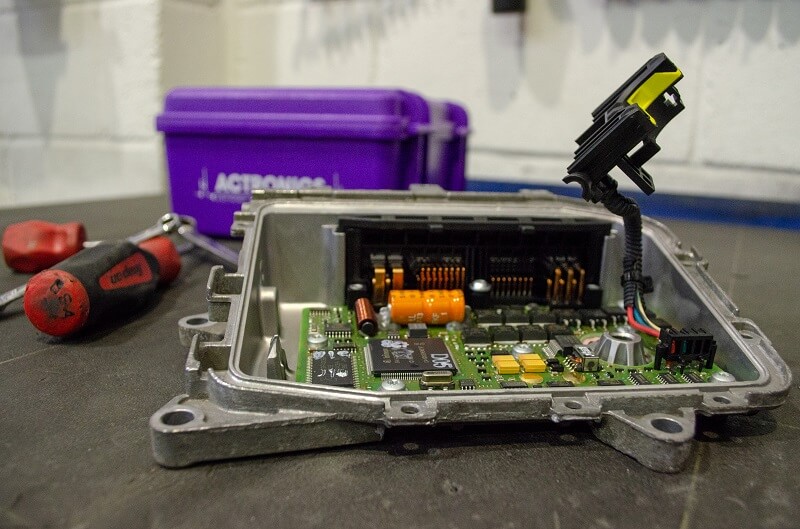

The mechatronics that control the clutch consists of a TCU, a clutch actuator and an electric motor, with each part having its own common faults.

These common faults mostly include:

These common faults mostly include:

- P1607 – Clutch Actuator Position Control Error

- P1609 – Clutch Actuator Position Sensor

- P1700 – Transmission Indeterminate Failure (Failed to Neutral)

Which will cause the following faults:

- Vehicle will not start

- Unable to select into gear and/or displaying an ‘F’ on the dash

- Gear changing is poor

As there are three parts to the mechatronics, the remanufacturing process can become complicated especially as there are multiple known components that can become defective.

Hardware components on the PCB of the TCU can become defective like any control unit and will require replacing if faulty.

Hardware components on the PCB of the TCU can become defective like any control unit and will require replacing if faulty.

The clutch pump can start leaking or become seized. If this happens a replacement pump is required.

If the electric motor has failed, this is usually down to the ‘brushes’ inside the unit becoming worn and/or seized. If this is the case, the ‘brushes’ will require to be replaced.

Because of these known components, the remanufacturing process will include replacing all of these to ensure that the unit is back to its original factory condition.

Some of the faulty electronic units we see, may have become faulty due to an external feature failing or due to poor vehicle maintenance, which could include:

- If the hydraulic fluid has not been changed with a service of the vehicle, over time this will lead to build up of contaminated fluid within the unit and will often lead to the mechatronic failing, but can continue to do so after remanufacture if the fluid is not flushed and replaced.

- Due to the location of the Crankshaft Position Sensor in the engine bay being external to the Easytronic unit, it is extremely common for it to become faulty from water contamination, fluctuating temperatures within the engine and becoming physically broken. This sensor being faulty can display codes; P0336-P0339 which can be mistaken for a mechatronic fault.

- If the clutch has become worn and in need of replacing, this could put excess strain onto the mechatronics, which could then become faulty.

When sending the unit back to customers, we remove the plastic clutch pump from the unit, because we have found that this becomes damaged during transit. If this is not fitted correctly, the unit will not re-learn its parameters and will fail to work on the vehicle.

da

da de

de es

es fr

fr it

it nb

nb nl

nl pt

pt sv

sv fi

fi