Why are PCBs / printed circuit boards always green?

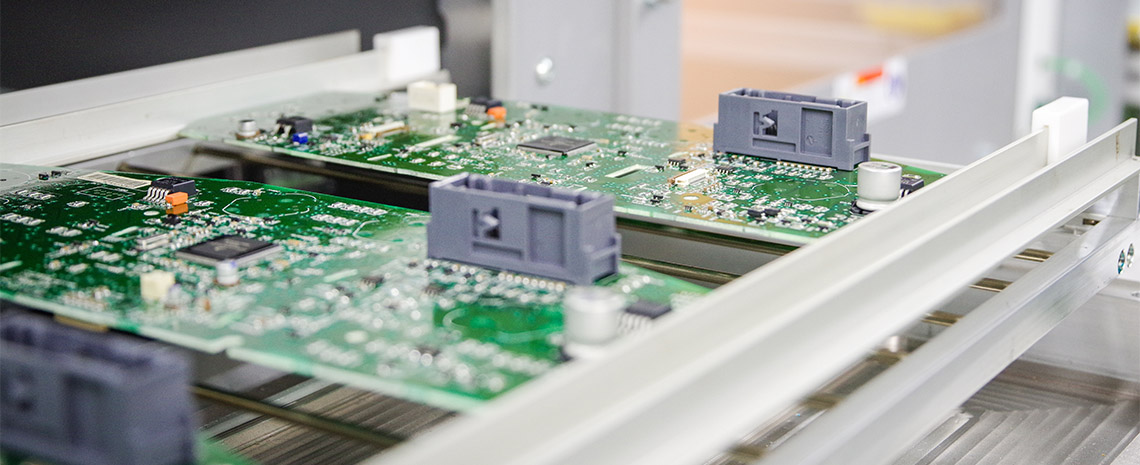

Anyone who walks into the remanufacturing department of ACtronics will often see another colour in addition to the purple work wear, that's the colour green! This has everything to do with the shiny printed circuit boards that can be seen at the various workstations. But why is a PCB actually green? Is there a reason for these green circuit boards? We went to investigate!

First of all, it might be good to explain what the green plate actually does. This layer, which is actually almost always green, is a solder mask. This mask is applied to the copper traces of a printed circuit board to insulate and protect against oxidation and to prevent solder bridges. A solder bridge is an inadvertent electrical connection between two conductors caused by soldering tin. A solder mask is essential for PCBs that are automatically soldered using reflow or wave soldering techniques. The various components are then placed on this protected green printed circuit board.

Various theories about green PCBs

Why are those PCBs normally supplied in the same colour? There are several theories about this. Here's a small overview:

- It would be based on old military requirements

- It would have been a matter of recognition. Most laminates developed at the time of the first printed circuit boards were already green. So it would provide recognition

- Green provides a great contrast if you printed white text on it, so it would also provide the greatest human response

- Mixing the hardener and the base resin would have resulted in a green colour and it was kept that way at the time

But which of these theories is correct, or is it a combination of the stories that makes for the truth? The green circuit boards are said to be the result of various experiments to make the circuit board just look nice visually. If you mixed the original resin and hardener together, you got a brown colour that didn't look very nice. The resin had a brown-yellow colour, while the hardener had a mud brown colour. Mixing this created a honey-like colour that wasn't exactly appealing. So it's the developers' task to come up with a nicer colour. They got to work with different pigments, first testing with red and blue. Red gave a rusty colour and blue a dark brown. So no success. When yellow pigment was used in the mixture in addition to the blue pigment, an acceptable green color was created that closely resembled the green hue that many laminate materials had at the time. This has ensured that green has been the standard for PCB production for decades.

Also in other colours?

Are printed circuit boards ever made in a different colour? Yes they are! Consider, for example, the printed circuit board of the Delphi Delco Multec, which is blue. Especially in the computer sector, manufacturers try to appeal to their target group with special and unique features, which undoubtedly include a different colour printed circuit board. Still, we don't see a red or pink circuit board in an ECU happening very quickly.

da

da de

de es

es fr

fr it

it nb

nb nl

nl pt

pt sv

sv fi

fi