Strong and weak points: the modern ECU in detail

The ECU is a wonderful piece of electronics. It is difficult enough to have so much functionality in such a small housing, but to make it function accurate and reliable in a surrounding that is ever changing is a formidable achievement. Though… the mentioned reliability is not always as good as it should be. How is it possible that the ECU, from time to time, does fault?

It is probably better if we start with an explanation of the technology that we find in the ECU, to be able to understand what weak points can be found. Nearly everybody knows that the ECU consists of a processor and memory soldered on to a PCB.

The PCB

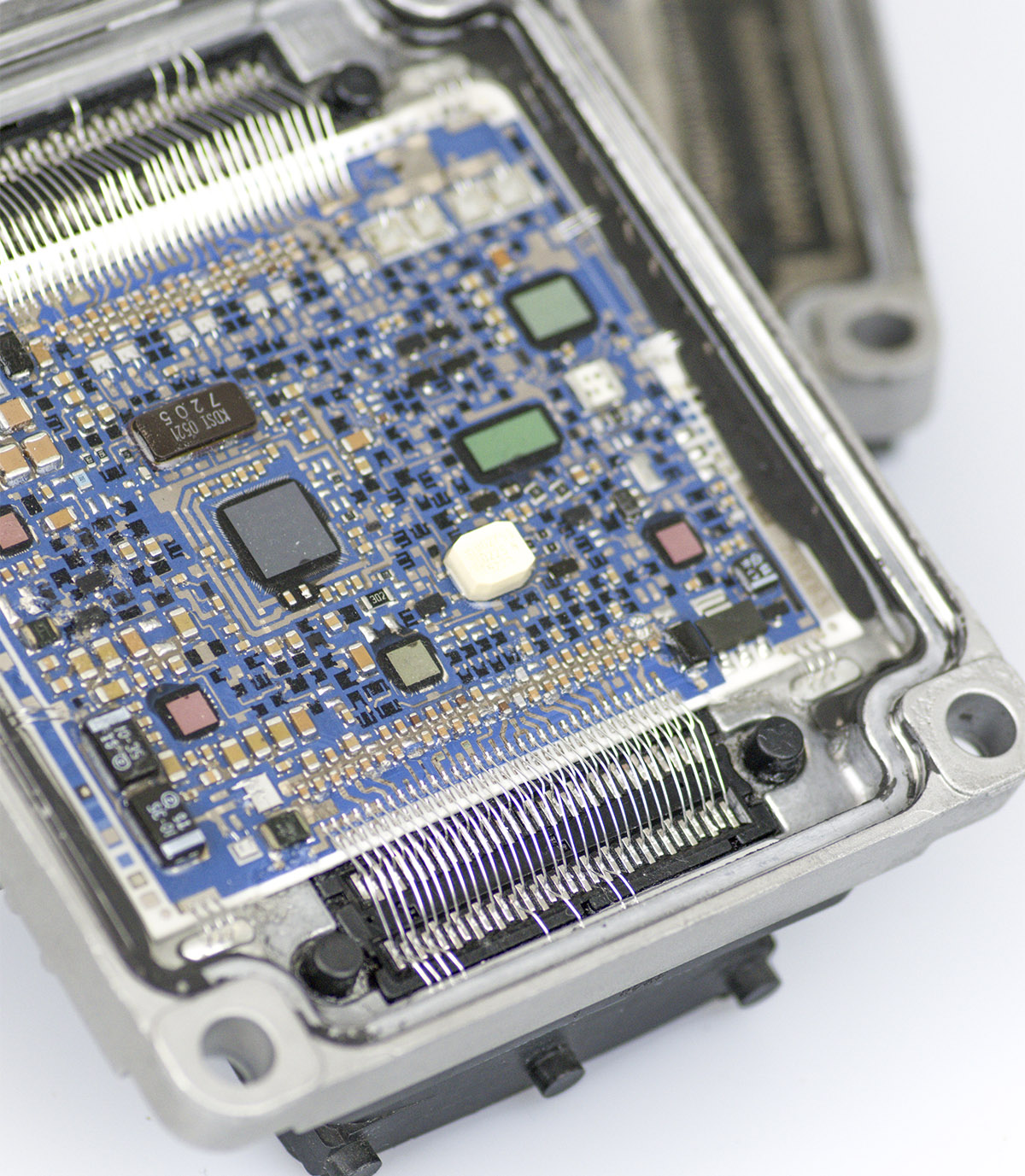

The PCB itself: the well-known green circuit board made of glass and epoxy is still widely used (ECUs by Bosch, FoMoCo and Siemens/VDO), but the introduction of ceramic material has made many manufacturers switch. The ceramic PCB is better in dissipating heat an is made of a finer, better structured material so it can be produced with great accuracy. This has it advantages for the design of the PCB because it is possible to create very small and even complex 3D structures. Car manufacturers like to use these advantages because every form of weight or space saving is welcomed. We expected to see these new ceramic PCBs more often in the near future.

Ceramic PCBs are nearly always glued to an aluminium base-plate with a thermal compound. This does not only help to dissipate the heat (created by the components) more quickly but also strengthens the PCB. Distortion and vibration caused damage of the PCBs is therefore less often noticed. Cracks and splits in the board itself are rarely seen either. The use of the ceramic boards has some real advantages over the trusty old green PCBs. We dare to go as far as saying that the old type PCBs are partially to blame for the varying reliability of some of the ECUs.

Components in and on the PCB

It won’t be a surprise to hear that this new type of PCBs uses different components. A conventional PCB is built coarser than the ceramic counterpart which makes the components themselves more robust. Most contacts are big enough to be seen with the naked eye. You would imagine that these components are more reliable than the smaller more fragile component on the ceramic PCB, but strangely enough the opposite seems to be true. Even larger modern components still fault. Could the low manufacturing costs play their part?

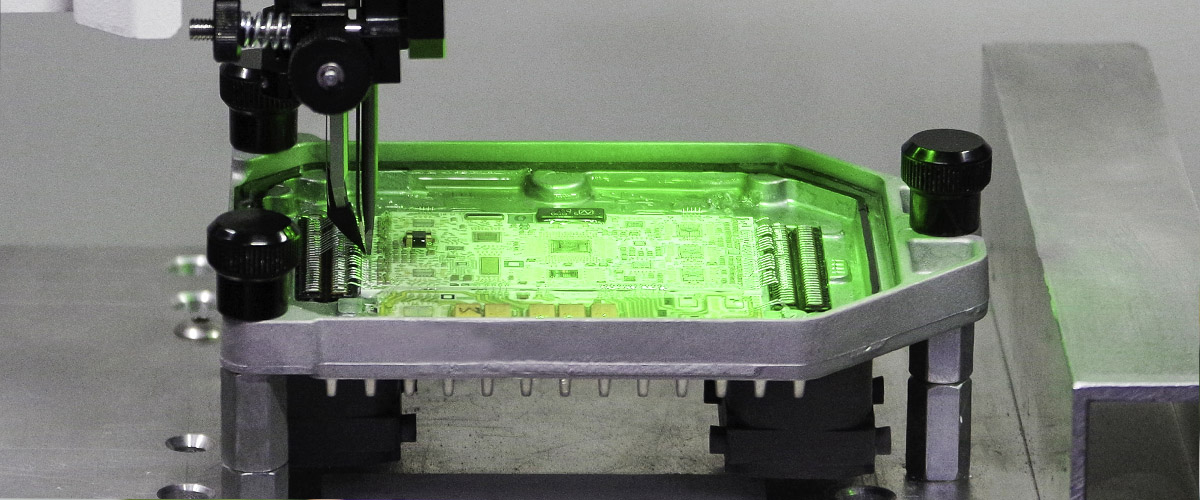

Using the right (solder-)equipment and skill a lot is possible in remanufacturing the connections and components on these often green PCBs. Even if the contacts are located on the bottom of the component as is the case in BGA processors. Though special equipment has to be used that can heat a specific local area.

A conventional PCB and the related components do fault from time to time, but remanufacture is in many cases a possibility. With components on ceramic circuit boards this process is not that straight forward.

Because of the size and complexity of the circuit board it is necessary to use smaller components. Heat dissipation is in the ceramic boards not a problem, even if embedded components are used. But when these delicate electronics fault, repair is not easy. Components are difficult, nearly impossible to reach and damage is easily done. The connections are often so small that it would not be possible to repair them without microscopes and specialised equipment. It would not impossible, but in every case, it should be evaluated if it is economically viable to repair the component.

Wire connections

ECU, because of the disadvantages of the old green PCB. Components seem to last longer because of the heat dissipation, stronger bonds that suffer less from deformation and vibration and a smaller, lighter and more complex design. There is one major disadvantage though, the wire connections. The ECU itself is not always the cause of the faults in these connections but we cannot deny that this is a weak point.

ECU, because of the disadvantages of the old green PCB. Components seem to last longer because of the heat dissipation, stronger bonds that suffer less from deformation and vibration and a smaller, lighter and more complex design. There is one major disadvantage though, the wire connections. The ECU itself is not always the cause of the faults in these connections but we cannot deny that this is a weak point.

da

da de

de es

es fr

fr it

it nb

nb nl

nl pt

pt sv

sv fi

fi