Yes really: ECUs are factory fitted in these special places

In today's car, electronic control units are indispensable. Every important part has a computer installed to control it. The 'father' of these computers is without a doubt the computer that controls the engine: the ECU. Over the years, however, this crucial part has had some special places in the car. We made a list!

Under the windscreen skuttle panel

When we say that water and electronics are not best friends, we're probably not telling you anything new. To mount an ECU directly under the windscreen does not immediately sound like a good idea. At the slightest leakage in the skuttle panel, water has all the room to leak onto the ECU. A few drops of water will not immediately cause many problems, but prolonged exposure can cause serious problems. However, it is a place reserved by different manufacturers to place the ECU. Well-known examples of ECUs mounted in this place are the Bosch EDC15V and Bosch EDC16C1. The Bosch EDC15V has been used in various V.A.G. models with the Volkswagen Caddy MK3 as a well-known example, while the Bosch EDC16C1 has been used in various BMWs like the BMW 3-series. The effect of long-term exposure to (rain) water is clearly visible in the photo shown.

In the interior

We do not know whether it is by definition a very bad place. The thing we do know, is that it's a very remarkable place! The Siemens Fenix 5, which was used in various Hyundai's and Kias' around the year 2000, is located in the interior of the car. Where the previous ECUs had a real chance of coming into contact with water, the chance is nil with this ECU. In the Hyundai Accent, for example, the ECU is mounted high and dry on the left under the dashboard against the A-pillar. If you have such a car in hand for the first time, it can therefore be a bit of a search to locate the ECU.

Directly on the engine

This is one that has been applied to several well-known cars over the years, so we have actually come to think of it as normal. But still it remains remarkable: mounting an ECU on the engine block. Just like moisture, vibrations are also not conducive to sustainable operation of the ECU. Well-known and also infamous examples are the Magneti Marelli IAW59F/59M/5AF/5AM that was used on the Fiat Punto 1.2 8V, the Delphi Delco Multec HSFI-2x/HDRC that was used between 2000 and 2008 on 1.6 litre petrol and 1.7 litre diesel engines and the Siemens Simtec 70 series used in the Vauxhall Astra G, Vectra B and Zafira B. The vibrations ensure that the fragile (solder) connections will tear over time and can become loose. This effect is amplified by the extreme temperature fluctuations to which an engine mounted ECU is subject. Due to these defects, numerous faults can occur.

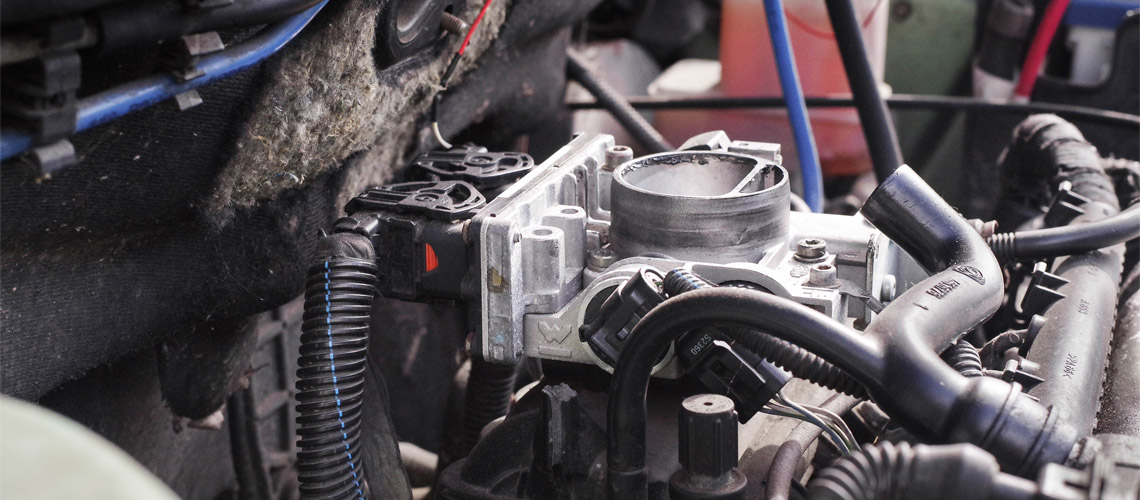

The special combinations in the Mercedes A-Class W168

Mercedes went one step further in the development of the Mercedes A-Class W168. They combined two components and integrated them into one part. The ECU and the mass flow meter were fused into one part. A combination that soon turned out not to be very reliable. In many cases, the engine did not run well. When a facelift of the W168 came in 2001, the ECU and the mass flow meter were separated. But even now the ECU did not become a stand alone part. This time the ECU and throttle body have been merged into one part. Miraculously, this solution turned out to be a lot more reliable than the original option, because the chance of a failure of this part turned out to be a lot smaller.

Bonus addition

It may not quite belong to this list, but it is too special not to share in this article. The BMW 850i from the 90s used a special principle. BMW used two 6-in-line engines that were merged into a V12. That's why the V12 also has two air intakes with two throttle valves and thus also two ECUs. The third ECU is to make everything run nicely in sync, but actually it is just 2 separate 6-in-line engines, each with their own electronics.

da

da de

de es

es fr

fr it

it nb

nb nl

nl pt

pt sv

sv fi

fi